This blog is a complete step-by-step guide on installing vinyl plank flooring directly over

concrete surfaces such as slabs, basements, stairs, and walls. It covers preparation of the

subfloor, moisture testing, different installation methods (floating, glue-down, peel-and-stick),

and post-installation care. The goal is to help users avoid common mistakes and choose the

right method,

If you’ve ever thought about updating a basement or a room with a concrete floor, you

probably already know the common problems. Concrete is hard, often uneven, and

sometimes it has moisture issues. Many people worry their new floor will end up cold, damp,

or even start peeling if it’s not installed right.

Vinyl plank flooring is a practical solution for these spaces. It can handle moisture, it feels

more comfortable underfoot than bare concrete, and it comes in different installation styles

like floating, glue-down, or peel-and-stick. That means you can match the method to your skill level and the condition of your floor.

In this guide, I’ll walk you through each step of installing flooring on concrete. I’ll

also share some lessons I’ve learned that can save you from the mistakes many beginners

make. By the end, you’ll feel more confident about tackling the project yourself.

Can You Install Vinyl Plank Flooring on Concrete?

Vinyl plank flooring can be installed on concrete, and in most cases it works really well.

Many homeowners choose it because it gives a modern look at a lower cost than wood or

tile. But like every option, it has strengths and some drawbacks to think about.

Pros

● Very durable and handles everyday wear without trouble

● Naturally waterproof, making it safe for kitchens, basements, and laundry rooms

● Wide range of designs and finishes that give concrete floors a warm, stylish look

Cons

● Concrete that holds moisture can cause damage if not sealed or treated first

● Uneven spots or cracks in the slab need repair before laying planks

● Cold surface without underlayment, vinyl can feel chilly underfoot

When Vinyl Isn’t the Best Choice

If your concrete slab has major moisture problems, such as constant dampness or leaks,

vinyl flooring may not last long. It’s also not the ideal pick for outdoor concrete or spaces that

face extreme temperature swings. In such cases, tile, polished concrete, or other floor types

may perform better.

Tools & Materials Checklist

Before you start, it’s important to gather all the necessary tools and materials. Having

everything ready not only saves time but also prevents mistakes during installation. Here’s a

complete list:

Vinyl planks

Available in floating (click-lock), glue-down, or self-adhesive types. Floating

planks are beginner-friendly, while glue-down options give a more permanent

finish.

Underlayment

Not always required, but it helps with sound reduction, comfort underfoot,

and smoothing out small imperfections in the concrete.

Adhesive

For glue-down installation, use a vinyl-specific adhesive that

bonds well with concrete and can withstand moisture.

Moisture barrier

A must if your concrete slab has any history of dampness. It

prevents water vapor from damaging your floor.

Spacers

These small tools ensure you leave a proper expansion gap

along walls, which keeps the floor from buckling later.

Utility knife or saw

A sharp utility knife works for most cuts, but a saw may be needed for

thicker planks or tricky areas.

Tapping block and mallet

Essential for click-lock flooring. They help secure planks

together tightly without chipping the edges.

Chalk line and measuring tape

These help you mark straight reference lines so the first row goes down

perfectly, avoiding crooked layouts.

Pro Tip

Always keep a few extra planks on hand. If one gets damaged during cutting or

installation, you’ll have a perfect match ready without halting your project.

Preparing Your Concrete Subfloor

Installing vinyl plank flooring on concrete may look simple, but the success of your project

depends heavily on the condition of the surface underneath. Concrete is strong, but it can

also hide problems like cracks, uneven spots, or hidden moisture. If these issues are

ignored, your planks may shift, separate, or wear out much faster than expected. That’s why

careful preparation is not just recommended, it’s the most important step before you even

open a box of flooring

Clean the Surface

Remove dust, dirt, and any sticky residues like carpet glue or paint. Even small debris can

stop planks from locking tightly together.

Fix Uneven Spots

Concrete floors often have dips or high spots. Use a self-leveling compound to smooth them

out. This prevents gaps or movement in your flooring later.

Repair Cracks

Hairline cracks can be sealed with filler, while larger cracks need proper patching. Leaving

them open can allow moisture to sneak in and damage the vinyl.

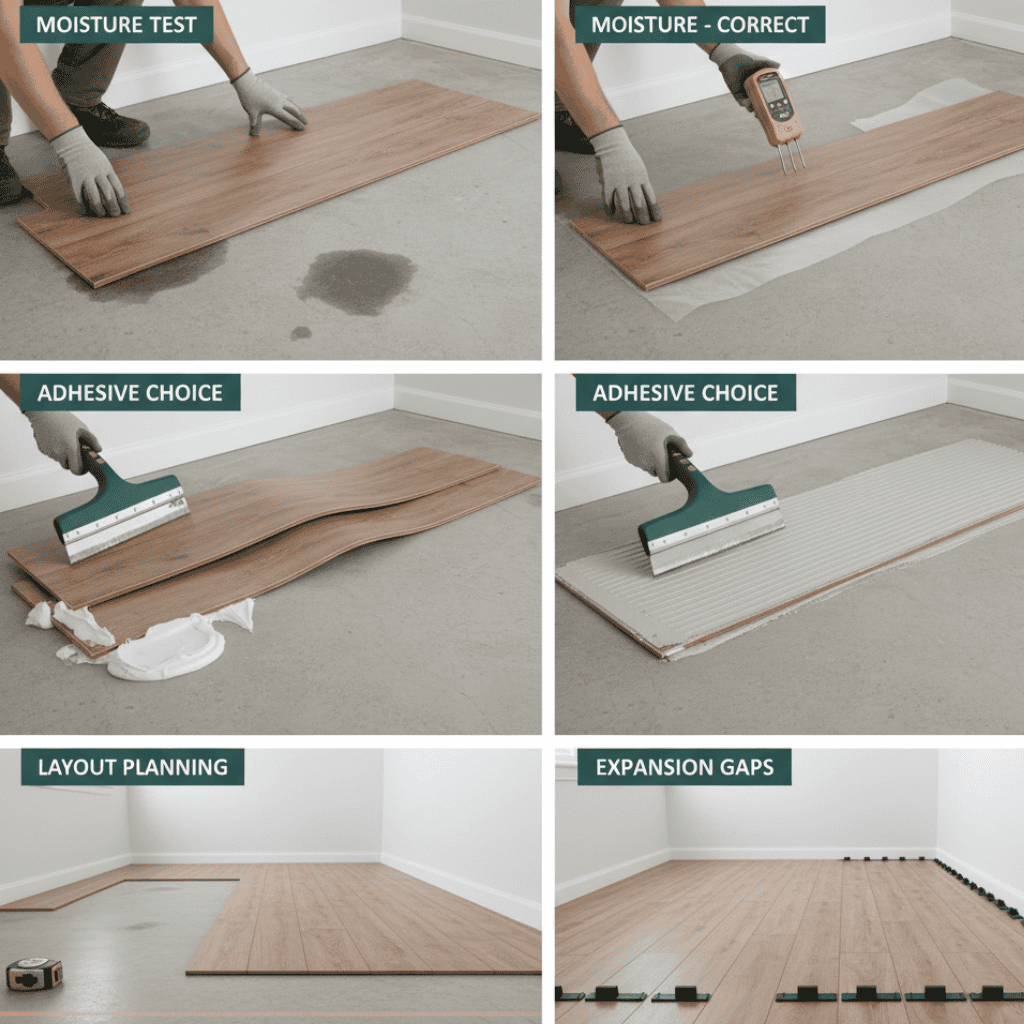

Test for Moisture

Basements and ground-level slabs often hold moisture. Place a plastic sheet overnight or

use a moisture meter to be sure. If moisture is present, use a barrier or sealant.

Decide on Underlayment

Underlayment isn’t always required, but it can add comfort, reduce sound, and act as extra

protection against cold concrete.

A properly prepared subfloor is like insurance for your flooring project it guarantees that your

vinyl planks will stay in place, look neat, and last for years without unexpected issues.

Why know what?

Many DIY installers skip moisture testing, but it’s the hidden reason why

floors lift, bubble, or smell musty later. Spending 10 minutes on this step can save you hundreds in repairs.

Ready to transform your concrete floor with vinyl planks?

Start by gathering the right tools

and checking your subfloor today. The sooner you prepare, the smoother your installation

will be.

Choosing the Right Installation Method

Not every vinyl plank is installed the same way. Concrete allows you to use floating,

glue-down, or peel-and-stick planks, but the right choice depends on your space, moisture

levels, and how permanent you want the floor to be.

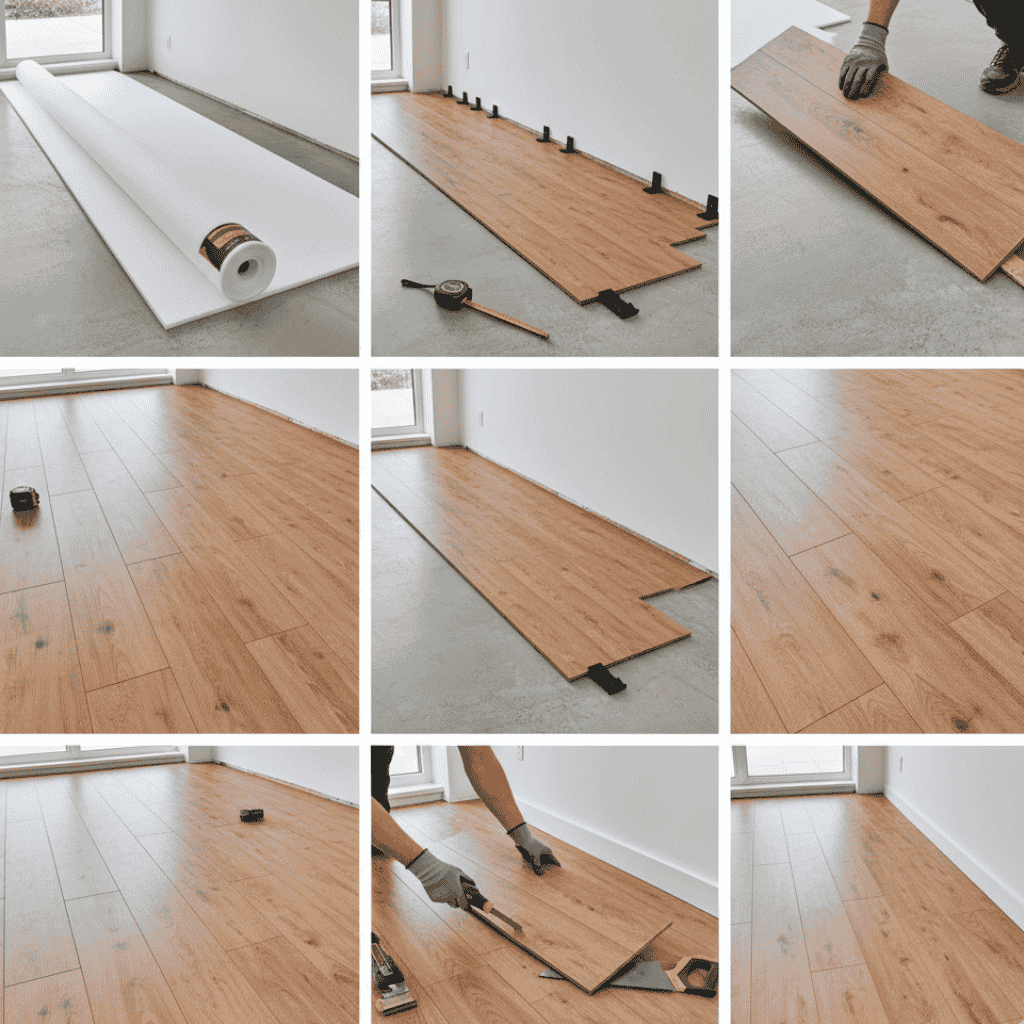

Floating / Click-Lock Vinyl Planks

Floating vinyl planks are the most beginner-friendly option. Instead of being glued down,

each plank locks into the next with a tongue-and-groove system and “floats” over the

concrete. This makes it one of the fastest ways to cover a concrete floor without dealing with

messy adhesives. Many homeowners prefer this method for living rooms, bedrooms, and

rental spaces because it’s easy to install, replace, or even remove later if needed.

● Pros: Easy for beginners, quick to install, easy to replace if a plank gets damaged.

● Cons: Needs a very level subfloor; may not feel as firm as glue-down.

Floating / Click-Lock Vinyl Planks

1. Lay an underlayment if required (this helps with comfort and sound).

2. Start at the longest and straightest wall in the room.

3. Place spacers along the wall to leave a small expansion gap.

4. Connect the planks by clicking the tongue-and-groove edges together.

5. Continue row by row, staggering the joints for a natural look.

6. Cut the last pieces to fit using a utility knife or saw.

7. Remove spacers and install baseboards or trim to cover the gaps.

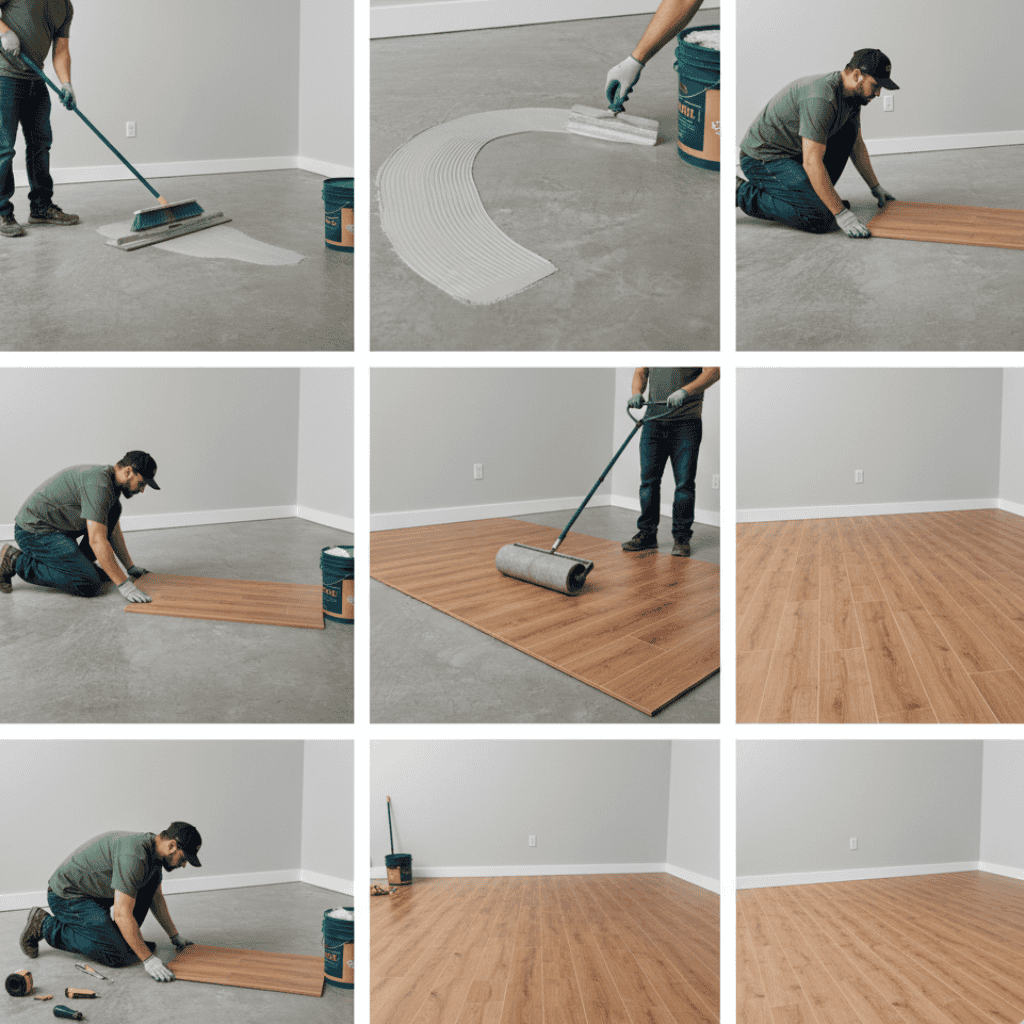

Glue-Down Vinyl Planks

Glue-down vinyl planks give a solid, permanent feel underfoot, making them ideal for busy

households and commercial spaces. Since each plank is secured directly to the concrete,

there’s no risk of shifting, but the prep work and installation require more effort compared to

floating floors.

● Pros: Feels solid underfoot, excellent for high-traffic areas, won’t shift.

● Cons: Harder to remove later; requires more prep work.

Steps to Install Glue-Down Planks:

1. Clean and dry the concrete; make sure it is smooth and level.

2. Apply a thin, even layer of adhesive using a notched trowel.

3. Start laying planks in one corner, pressing each piece firmly into the adhesive.

4. Work in small sections so the glue doesn’t dry before you place the planks. 5. Use a 100-lb roller across the floor to press the planks down evenly.

6. Allow the adhesive to cure fully (usually 24 hours) before walking heavily on the floor.

Peel-and-Stick / Self-Adhesive Vinyl Planks

Peel-and-stick planks are the quickest and most affordable option, perfect for small rooms or

temporary updates. They come with adhesive backing, so installation is as simple as peeling

and pressing but they don’t hold up as well in damp areas like basements.

● Pros: Budget-friendly, fast to apply, no extra tools required.

● Cons: Adhesive may weaken in humid areas, and it is not ideal for basements.

Steps to Install Peel-and-Stick Planks:

1. Clean and dry the concrete thoroughly dust or moisture will ruin adhesion. 2. Peel the backing off the plank carefully.

3. Place the plank starting from one corner, and press it firmly onto the floor.

4. Smooth out each piece with a hand roller or pressing tool to remove air bubbles.

5. Continue row by row, trimming pieces as needed.

6. Once finished, avoid mopping or heavy use for 24 hours to let the adhesive bond

fully.

Quick Comparison: Vinyl Plank Installation Methods on Concrete

Why know what?

If you want a quick DIY project, go for floating planks. If durability is a priority,

glue down is the smarter choice. Peel-and-stick should be reserved for light use rooms.

Step-by-Step Installation Guide for Vinyl Plank on Concrete

Installing vinyl planks on concrete may look straightforward, but following a proper sequence

is what makes the difference between a professional finish and a floor that lifts, gaps, or

looks uneven. Here’s a complete breakdown:

1. Layout Planning

Before you cut a single plank, map out your room. Snap a chalk line or use a laser guide

along your starting wall. Decide whether you’ll run the planks parallel to the longest wall or

towards the main source of natural light. Both approaches create a more natural visual flow.

Always calculate the plank widths in advance so you don’t end up with a thin, awkward strip

on the final row.

2. Allow for Expansion Gaps

Vinyl expands and contracts with temperature changes. Leave at least a 1/4-inch gap along

all walls, pillars, and fixed objects. Use spacers to maintain this distance throughout the

install you’ll cover it later with baseboards or trim.

3. Installing the First Row

The first row determines the alignment of your entire floor. Start at your marked line,

ensuring the planks are perfectly straight. If using click-lock planks, angle the tongue into the

groove and lock them tight. For glue-down, spread adhesive in small sections with a notched

trowel and press planks firmly. Always double-check alignment before moving forward.

4. Staggering Seams for a Natural Look

Rows should never end with seams that align directly across. Stagger end joints by at least 6

inches between rows. This not only strengthens the structure but also mimics the natural

variation of real hardwood. Use off-cuts from one row to begin the next where possible, it

saves material and keeps the pattern organic.

5. Trimming Planks for Edges & Corners

When you reach the edges, doorways, or vents, measure carefully and mark your planks

before cutting. A utility knife works for straight cuts, while a jigsaw or oscillating tool is better

for notches and detailed trimming. Slide trimmed planks into place, keeping expansion space

intact.

6. Sealing and Finishing Touches

Once the planks are down, remove the spacers around the walls. Install baseboards, quarter

rounds, or transition strips to cover expansion gaps and create a polished finish. In

bathrooms, kitchens, or basements, consider sealing edges with waterproof silicone caulk

for extra protection against moisture seepage.

Pro Tip

Never rush the final rows. These usually require more trimming and precise fitting,

and a mistake here is the first thing visitors will notice.

Special Situations When Installing Vinyl Plank on Concrete

Most vinyl plank flooring projects are straightforward, but sometimes you’ll face tricky

situations like stairs, basements, or uneven concrete. Each of these requires a slightly

different approach to get long-lasting results.

Installing Vinyl Plank Flooring in a Basement

Basements are naturally prone to dampness, which makes moisture control the top priority.

Always perform a moisture test first, and if needed, install a moisture barrier before laying

planks. Floating or glue-down vinyl both work, but avoid peel-and-stick since humidity can

weaken adhesives.

Installing on Stairs

Stairs demand more precision and durability than flat floors. Each tread and riser should be

measured and cut separately. Glue-down planks work best here because they won’t shift

underfoot. Don’t skip stair nosing it makes the edges safe and professional-looking.

Installing on Uneven or Rough Concrete

Vinyl flooring requires a flat, stable surface. If your concrete has dips, cracks, or high spots,

use a patching compound or self-leveling underlayment. Skipping this step risks gaps, noise,

or broken locking systems later.

Installing Vinyl Plank Flooring on a Concrete Wall

For those creating a feature wall, peel-and-stick or glue-down planks are your best options.

Ensure the wall is clean, smooth, and completely dry. Start at the bottom and work your way

up, pressing each plank firmly so it bonds without slipping.

You know what?

Always match the installation method to the environment. Basements need waterproofing, stairs need adhesive, and walls need lightweight planks for a secure hold.

Not sure if your concrete is ready for vinyl plank flooring?

Get a quick consultation

with a flooring professional before starting your project.

Finishing Touches After Installing Vinyl Plank Flooring on Concrete

Once the planks are in place, a few finishing touches make your floor look polished and help

it last longer. These steps often get overlooked, but they make a big difference in the final

result.

Sealing Edges & Transitions

Seal the edges where your flooring meets walls, cabinets, or doorways with appropriate

caulk or transition strips. This prevents moisture from seeping underneath and gives the floor

a smooth, finished appearance.

Adding Baseboards or Trims

Reinstall or add baseboards and quarter-round trims to cover the expansion gaps you left

around the edges. This not only hides gaps but also gives your floor a clean, professional

look.

Furniture Protection

Heavy furniture can dent or scratch vinyl over time. Use felt pads under chairs, couches, or tables, and avoid dragging furniture across the surface. For rolling chairs, consider a protective floor mat.

Pro Tip

Give your floor at least 24 hours before moving heavy furniture back into the

room. This allows adhesives (if used) to set and planks to settle properly.

Maintenance & Longevity Tips

Once your vinyl plank flooring is installed, proper care will keep it looking new and extend its

life. The good news is that vinyl requires minimal maintenance compared to other flooring

types, but a few smart habits make a big difference.

Regular Cleaning

Sweep or vacuum often to remove dirt and grit that could scratch the surface. A

damp mop with a mild cleaner is usually all you need.

Preventing Water Damage

While most vinyl planks are water-resistant, avoid letting standing water sit on the

floor, especially around edges or seams.

Furniture Protection

Use felt pads under chairs, tables, and heavy furniture to prevent dents or scratches.

Avoid Harsh Cleaners

Skip abrasive scrubbers or strong chemicals, as they can dull the finish.

Long-Term Care

Rotate rugs and furniture occasionally to prevent uneven fading and wear in

high-traffic spots.

Important Note

With these simple steps, your vinyl plank flooring on concrete can stay beautiful and durable for 15–20 years or more.

Common Mistakes to Avoid

Even though vinyl plank flooring is DIY-friendly, a few missteps can lead to costly repairs or a

floor that doesn’t last as long as it should. Here are the most common mistakes to watch out

for:

● Skipping the moisture test Concrete can hold hidden moisture that may damage your floor over time. Always test before installing.

● Using the wrong adhesive Not every glue works with vinyl planks on concrete.

Make sure to choose an adhesive designed specifically for vinyl flooring.

● Forgetting expansion gaps Vinyl needs room to expand and contract. Without a

1/4-inch gap around walls and fixed objects, the planks may buckle.

● Rushing the layout Starting without a proper plan can leave you with thin,

awkward strips along the last wall. Take time to measure and plan your layout.

Important Note

A little extra prep goes a long way. Avoid these mistakes, and you’ll

have a smooth, professional-looking floor that lasts for years.

Conclusion: Installing Vinyl Plank Flooring on Concrete the Right Way

Installing vinyl plank flooring on concrete isn’t as hard as it looks. Once your subfloor is

clean, level, and dry, the rest is just choosing the right method floating for ease, glue-down for durability, or peel-and-stick for quick fixes. With a little planning and patience, you can get

a smooth, stylish floor that lasts.

Of course, if your space has tricky spots like stairs or a basement with moisture, it’s perfectly

fine to call in a pro. But for most DIYers, this is one project you can tackle confidently.

Vinyl Plank Flooring on Concrete – FAQs and Expert Answers

Not always. Floating planks often perform better with an underlayment because it adds

comfort underfoot, reduces sound, and provides a moisture barrier. Glue-down planks

usually don’t need underlayment, but in damp areas like basements, adding a thin vapor

barrier can save your floor from long-term damage.

A high-quality pressure-sensitive adhesive is recommended for most glue-down

installations. This type holds the planks firmly but still allows slight flexibility for expansion. In

high-moisture areas, a moisture-resistant adhesive is best. Always check the flooring brand’s

instructions before choosing one.

No, uneven concrete will cause planks to shift, gap, or wear out faster. Before starting, fill

cracks with patching compound and use a self-leveling product to smooth out dips. Taking

this extra step ensures your flooring stays tight and professional-looking for years.

Yes, most modern vinyl plank flooring is 100% waterproof. That’s why it’s popular in

basements, kitchens, and bathrooms. However, water can still seep in through the edges if

not sealed properly, so always use transition strips and silicone caulking where needed.

The timeline depends on your method and room size. A small bedroom can be done in

4–6 hours with floating planks, while glue-down flooring may take a full day due to adhesive

curing time. Preparation, like leveling and cleaning the subfloor, often takes just as long as

laying the planks.

Yes, vinyl planks can go straight on a basement concrete slab, but only if it’s dry and

level. Basements often have hidden moisture issues, so doing a moisture test first is crucial.

For extra protection, install a vapor barrier under the planks.

Floating or click-lock vinyl planks are the best choice for DIYers. They don’t need glue,

special tools, or advanced skills just snap them together like a puzzle. Even if you make a

mistake, you can unlock and reset the planks without wasting material.

Yes, but the process is more detailed. Glue-down planks are recommended because they

stay secure under heavy foot traffic. Each step should be measured, cut, and glued carefully,

and nosings must be properly finished for safety. It’s a bit more advanced than flat surfaces.

Maintenance is simple. Sweep or vacuum regularly to keep grit from scratching the

surface. Use a damp mop with mild cleaner for deeper cleaning, avoiding soaking the floor or

using wax-based products. Adding felt pads under furniture will also prevent dents and scratches.

The most common mistake is skipping the moisture test. Even if your concrete looks dry,

hidden moisture can ruin adhesives and warp the planks over time. Other mistakes include

not leaving expansion gaps, rushing the layout, or failing to level the subfloor.