The easiest way to cut vinyl plank flooring is by using the score-and-snap method.

Measure the plank, mark your cut line, and use a sharp utility knife with a straight edge to score several times. Then bend the plank upward until it snaps cleanly. For curves or corners, use a jigsaw with a fine-tooth blade for smooth, precise cuts.

Installing vinyl plank flooring can change the look of any room and make it feel new. When I

started my first flooring project, I quickly learned that cutting the planks the right way was the

key to a perfect fit. A clean and straight cut helps the planks fit tightly together, saves

material, and gives the floor a neat, smooth finish.

Cutting vinyl planks isn’t hard if you use the right tools and take your time. Simple tools like a

utility knife, ruler, and straight edge are often enough. Working safely and carefully will help

you avoid mistakes and get the job done faster. Once you learn the right way to cut,

installing vinyl flooring becomes much easier and more enjoyable.

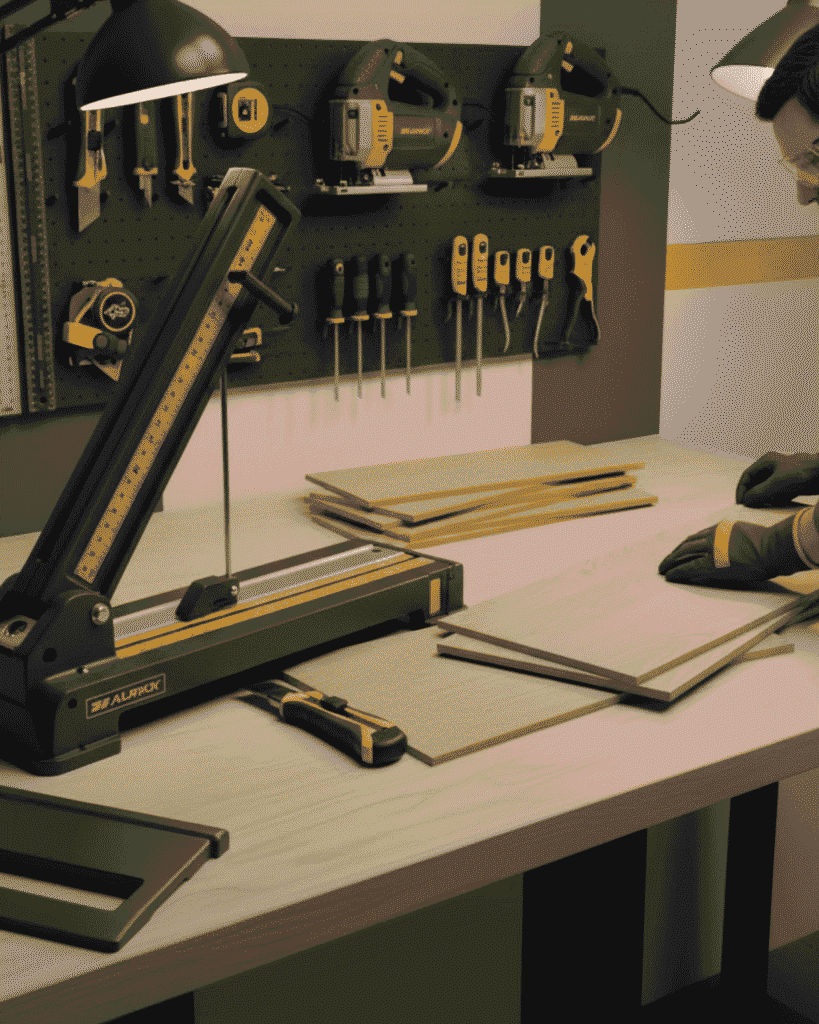

Essential Tools You’ll Need (Pro Picks for Clean Cuts)

Having the right tools makes cutting vinyl flooring faster and neater. Here’s what you’ll need:

● Utility knife

● Vinyl plank cutter (guillotine-style)

● Jigsaw or circular saw

● Straight edge or T-square

● Measuring tape and pencil

● Safety gear (gloves and glasses)

A sharp utility knife is perfect for most straight cuts, while a jigsaw helps handle curves or

detailed shapes. Always double-check your blade before starting. A dull blade can tear the

plank surface instead of cutting cleanly.

Best Tools for Cutting Vinyl Plank Flooring Compared & Rated

Not all tools give the same results. Here’s a quick look at which tool fits your project best:

Pro Tip

If you’re doing a full-room install, invest in a plank cutter it’s faster, cleaner, and

pays for itself after one project.

How to Choose the Best Tool for Cutting Vinyl Plank Flooring (Based on Your Skill & Budget)

Choosing the right cutting tool makes a big difference in how smooth and stress-free your

flooring project goes. You don’t always need expensive equipment the best tool depends on

your skill level, project size, and the type of planks you’re using.

If you’re a beginner or working in a small space:

Start simple with a utility knife and a straight edge. These are safe, affordable, and perfect for quick score-and-snap cuts. You’ll be surprised how neat your results look with just a bit of patience.

For medium-sized rooms or multiple areas:

A vinyl plank cutter (guillotine-style) is worth the investment. It cuts clean, straight edges with little effort and no dust. It’s quieter than power tools and ideal if you’re doing a full-room install.

If your project includes corners, vents, or door frames:

Keep a jigsaw handy. It’s the best tool for curves and detailed shapes. Choose a fine-tooth

blade and move slowly to avoid chipping the surface.

For professionals or experienced DIYers:

A circular saw or miter saw offers precision and speed, especially for long, straight cuts or

thicker SPC planks. Always wear safety gear and take your time lining up each cut.

Important Note:

Don’t rush to buy every tool at once. Start with a utility knife, you can

always upgrade later once you feel confident with your cutting technique and project scale.

Safety & Workspace Preparation (Before You Start Cutting)

Safety should come first before you make the first cut. Clear your workspace to avoid

tripping hazards and make sure you have enough lighting. Always wear gloves to protect

your hands and safety glasses to keep debris away from your eyes.

Set up a stable cutting surface a workbench or a flat piece of plywood works well. Keep

tools within easy reach but out of your main movement area. A well-organized space makes

cutting smoother and safer from start to finish.

How to Cut Vinyl Plank Flooring (Step-by-Step)

Cutting vinyl planks the right way helps you get a clean finish and a perfect fit. Follow these

simple steps for accurate, smooth cuts.

Step 1 – Measure and Mark Your Cut Line (Accuracy Matters)

Use a tape measure to find the exact length you need. Mark your line lightly with a pencil,

using a T-square or straight edge to keep it straight. Always double-check before cutting. Accurate marking saves you from wasted planks.

Step 2 – Score the Plank (Create a Clean Break Point)

Place the straight edge on your mark and score along it with a sharp utility knife. Apply steady pressure and score a few times rather than trying to cut through in one go. This helps

Create a clear groove for snapping.

Step 3 – Snap the Plank (Smooth, Even Separation)

Hold the plank with both hands and gently bend it backward along the scored line. It should snap cleanly in two pieces. For thicker planks, you can rest the score line on the edge of a table or a block for extra support while snapping.

How to Cut Vinyl Plank Flooring for Different Situations

Every home has areas that need extra attention when cutting vinyl planks corners,

doorways, or edges that don’t fit the standard straight-line cuts. Learning how to handle each

situation saves time and keeps your floor looking professional. With the right tools and

approach, you can make clean, precise cuts that fit perfectly around every detail of your

room.

Cutting Straight Lines (Using a Utility Knife or Cutter)

For most planks, the score and snap method is the easiest and cleanest option. Mark your

cut line with a pencil, place a straight edge on top, and score the surface several times with

a utility knife. Then, bend the plank gently until it snaps apart. This simple method works

great for end cuts and adjustments along walls.

Cutting Around Objects or Corners (Using a Jigsaw)

When dealing with corners, vents, or pipes, make a cardboard template first. Trace the

shape you need onto the plank, then cut along the outline using a jigsaw. Move slowly and

let the blade do the work to avoid rough edges or cracks.

Cutting Lengthwise or Long Ways

For long, narrow cuts, use a table saw or circular saw. These tools keep your edges straight

and clean. Mark your cut carefully and guide the plank steadily through the blade. This type

of cut is common near walls or when fitting planks at the end of a row.

Cutting Around Door Jambs

Instead of cutting planks to fit around door trims, undercut the trim slightly using a small

hand saw or oscillating tool. This allows you to slide the plank underneath for a smoother,

more seamless look. It’s a small detail that makes your installation look professionally done.

Pro Tip

Before cutting any planks for tight spaces, test-fit them first. This helps you double-check your measurements and avoid wasting material if a cut is slightly off.

How to Cut Vinyl Plank Flooring Without a Cutter

You don’t always need a special vinyl cutter to get the job done. With a few simple tools and a steady hand, you can make clean, accurate cuts using what you already have at home.

If you’re working without a vinyl plank cutter, a utility knife or a jigsaw works just as well. First, measure and mark your cut line clearly with a pencil and a straight edge. Then score the surface several times with the knife, applying firm and even pressure. Bend the plank along the scored line until it snaps cleanly apart. For more detailed cuts like fitting around corners or vents, a jigsaw is your best option. Go slow and follow your marked line carefully. Always use a fine-tooth blade for smoother

edges.

You know what ?

When using a utility knife, make multiple light passes instead of one deep cut. This gives you more control and keeps the edges straight without damaging the plank surface.

Cutting Different Types: SPC vs WPC vs LVT (Material-Based Tips)

Not all vinyl planks are made the same, and the way you cut them can affect both the finish

and the fit. Each core type SPC, WPC, and LVT reacts differently to pressure, temperature,

and cutting tools. Understanding these differences ensures clean cuts, fewer mistakes, and

a smoother installation overall.

SPC (Stone Plastic Composite)

SPC planks are known for their solid, stone-based core that makes them extra tough and

rigid. Because of this density, cutting them takes more effort than softer flooring types.

● Use a vinyl plank cutter, circular saw, or miter saw for best results.

● Avoid trying to bend or snap them like flexible vinyl; they can crack.

● When cutting with a saw, go slowly and use fine-tooth blades to prevent chipping.

● Always wear safety glasses since SPC dust can be fine and sharp.

- Best for: Apartments, kitchens, and DIY projects where flexibility and ease of use are key.

WPC (Wood Plastic Composite)

WPC planks have a wood-and-plastic composite core that makes them slightly softer and

easier to cut than SPC. They offer a bit of flexibility, so you can use hand tools more easily.

● A utility knife or jigsaw works well for most cuts.

● For smooth edges, score the surface several times before snapping.

● To prevent surface chipping, cut with the decorative side facing up.

● If using a power saw, keep the speed moderate too fast can cause small tears.

- Best for: Living rooms, bedrooms, and light commercial spaces where comfort and style meet strength.

LVT (Luxury Vinyl Tile)

LVT is the most flexible and beginner-friendly type. Its thinner structure allows quick, easy

cutting with simple tools, perfect for DIY installers.

● Use the score-and-snap method with a sharp utility knife.

● Apply steady pressure and bend along the cut line to separate cleanly.

● LVT is ideal for precise trimming around corners or vents without special tools.

● For detailed or curved cuts, a small jigsaw gives cleaner edges.

Best For

Pro Tip

Common Mistakes to Avoid When Cutting Vinyl Plank Flooring

Cutting vinyl planks is easy once you know how, but a few small mistakes can cause wasted

materials or uneven edges. Avoiding these common errors will help you get a smooth,

professional-looking result every time.

1. Rushing the measuring step. Always double-check your measurements before

cutting. A small mistake here can throw off your entire layout.

2. Using dull blades A dull knife or saw blade can tear the vinyl instead of slicing it

cleanly. Replace blades often for smooth, precise cuts.

3. Skipping safety gear Gloves and safety glasses protect you from slips or small flying

pieces. Take a minute to gear up before starting.

4. Cutting without a straight edge, Freehand cuts often come out uneven. Use a ruler or

T-square to keep lines perfectly straight 5. Forcing the plank to snap. If a plank doesn’t break easily, score it a few more times

instead of bending too hard. This prevents cracks or rough edges.

Pro Tip

Take your time during the first few cuts. Once you get a feel for how the material reacts, the

rest of the job becomes faster and easier.

How to Cut Vinyl Plank Flooring After Installation (Quick Fixes & Adjustments)

Sometimes, you’ll need to trim a plank that’s already installed, maybe for vents, trim, or

last-minute adjustments.

Here’s what to do:

● Mark the section that needs trimming carefully.

● Use a multi-tool or oscillating saw for small, precise cuts.

● For larger sections, remove the plank if possible and cut outside.

● Reinstall the piece gently to maintain a tight fit.

Important Note

Protect the surrounding planks with masking tape when cutting in place it prevents accidental scratches.

Pro Tips from Experience

The best tricks aren’t in manuals, they come from real job sites. Here are lessons the pros

live by:

● Change blades often. A sharp blade gives clean cuts and keeps edges smooth.

● Cut face-up for better results, especially on decorative planks. This prevents surface

chipping.

● Keep your workspace stable. Even a small movement can throw off your cut line.

● Use scrap pieces to test cuts. It helps you check blade depth and pressure before the

real cut.

● Work with light behind you so you can clearly see markings and grain direction.

● Plan your layout first. Knowing where tricky cuts will land saves you wasted material

later.

Conclusion: Master the Art of Cutting Vinyl Plank Flooring

Cutting vinyl plank flooring may seem tricky at first, but with the right tools, a steady hand,

and a bit of patience, anyone can do it. Whether you’re working around corners, trimming

door frames, or cutting full-length planks, accuracy comes with practice.

Always remember: measure twice, cut once. Working safely and taking your time will save

you money, prevent damage, and give you a clean, professional finish that looks like it was

installed by an expert. Once you get the hang of it, cutting vinyl planks becomes a quick and

satisfying part of your flooring project and the results will make your space look brand new.

FAQs About Cutting Vinyl Plank Flooring

The easiest and most beginner-friendly method is the score-and-snap technique. Measure

your plank carefully, mark your cut line, and use a utility knife with a straight edge to score

several times.

Once the line is deep enough, bend the plank upward until it snaps cleanly. It’s safe, quick,

and works perfectly for most standard vinyl planks without any power tools.

Yes, you can use common saws such as a circular saw, jigsaw, or miter saw. However,

make sure to use a fine-tooth blade to prevent rough edges or chipping.

Always cut with the decorative side facing up, and move the blade slowly to maintain

control. Using the right blade type makes a big difference in getting clean,

professional-looking results.

At minimum, you’ll need a utility knife, a straight edge, a tape measure, and a pencil for

marking. For cleaner and faster work, tools like a vinyl plank cutter, jigsaw, or circular saw

are helpful.

Always keep a sharp blade and wear gloves and safety glasses to avoid accidents. Having

The right setup not only saves time but ensures every cut fits precisely.

Cutting around irregular shapes like corners or pipes is easy if you plan first. Create a

cardboard or paper template of the area, trace it onto the plank, and then cut along the line

using a jigsaw.

This ensures accuracy and prevents wasted material. For tighter spaces, make several

small cuts instead of one deep cut to keep the edges neat.

Yes, you can make small adjustments even after installation. Use a utility knife or oscillating

multi-tool for trimming edges or fitting planks near walls.

Be sure to cut slowly and protect surrounding planks with painter’s tape. It’s best for a minor

fixes if you need to resize multiple planks, it’s smarter to remove and re-cut them before

reinstalling.

To prevent chipping, always use sharp, clean blades and apply even pressure. Cutting too

quickly or using dull tools can tear the surface layer.

Support the plank fully while cutting and, if using a saw, keep the decorative side facing

upward. Patience and precision go a long way toward a perfect, smooth finish.

Yes, letting planks acclimate is an important step. Leave them in the room for at least 24

hours before cutting or installing.

This allows the material to adjust to temperature and humidity levels, preventing expansion

or contraction after installation. Skipping this step can cause gaps, lifting, or misaligned

seams later on.

Planks usually crack when they’re too cold or when too much pressure is applied too

quickly. Dull blades or not scoring deeply enough can also cause breaks.

To fix this, let the planks warm to room temperature, score several times with a sharp knife,

and snap gently. If using a saw, cut slowly with steady control.

SPC (Stone Plastic Composite) is the hardest type and often needs a vinyl cutter or saw.

WPC (Wood Plastic Composite) is softer and can be scored with a utility knife easily. LVT

(Luxury Vinyl Tile) It is flexible, thin, and perfect for the score-and-snap method.

Knowing your plank type helps you choose the right cutting approach for cleaner, safer

results.

If your room has complex corners, lots of doorways, or detailed layouts, hiring aA

professional can save time and reduce waste.

Pros use precision tools for tight fits around obstacles. However, for straightforward rooms

or DIY projects, most homeowners can handle cutting themselves with patience and basic

tools.