This guide covers the most common mistakes vinyl plank flooring installation.

including subfloor prep, acclimation, expansion gaps, cutting errors, and layout issues.

Room-specific challenges like bathrooms, basements, and open-concept areas are included.

Maintenance tips and pro advice help your floor last longer, whether DIY or hiring a

professional, following these steps prevents damage, gaps, and voided warranties..

Vinyl plank flooring has become a favorite for many homeowners because it’s durable,

water-resistant, and easy to install. It looks great, feels comfortable underfoot, and is often a

top choice for DIY projects.

However, even a small common mistakes vinyl plank flooring installation can lead to gaps, buckling, uneven surfaces, or wasted money. Many DIYers and first-time installers overlook simple steps that

could save them time and frustration.

In this guide, we’ll go through the most common mistakes people make when installing vinyl

plank flooring, explain what can go wrong, and give you practical tips to avoid them. In situations where precision matters, flooring installation services provide consistent results across different flooring types. By the end, you’ll have the confidence to either tackle the project yourself or know when to call a

professional.

Ready to get started?

Proper preparation is the key to a smooth, long-lasting floor. Gather your tools, check your subfloor, and take the first step with confidence to avoid the common mistakes that cause gaps, lifting, or uneven planks.

15 Common Mistakes When Installing Vinyl Plank Flooring

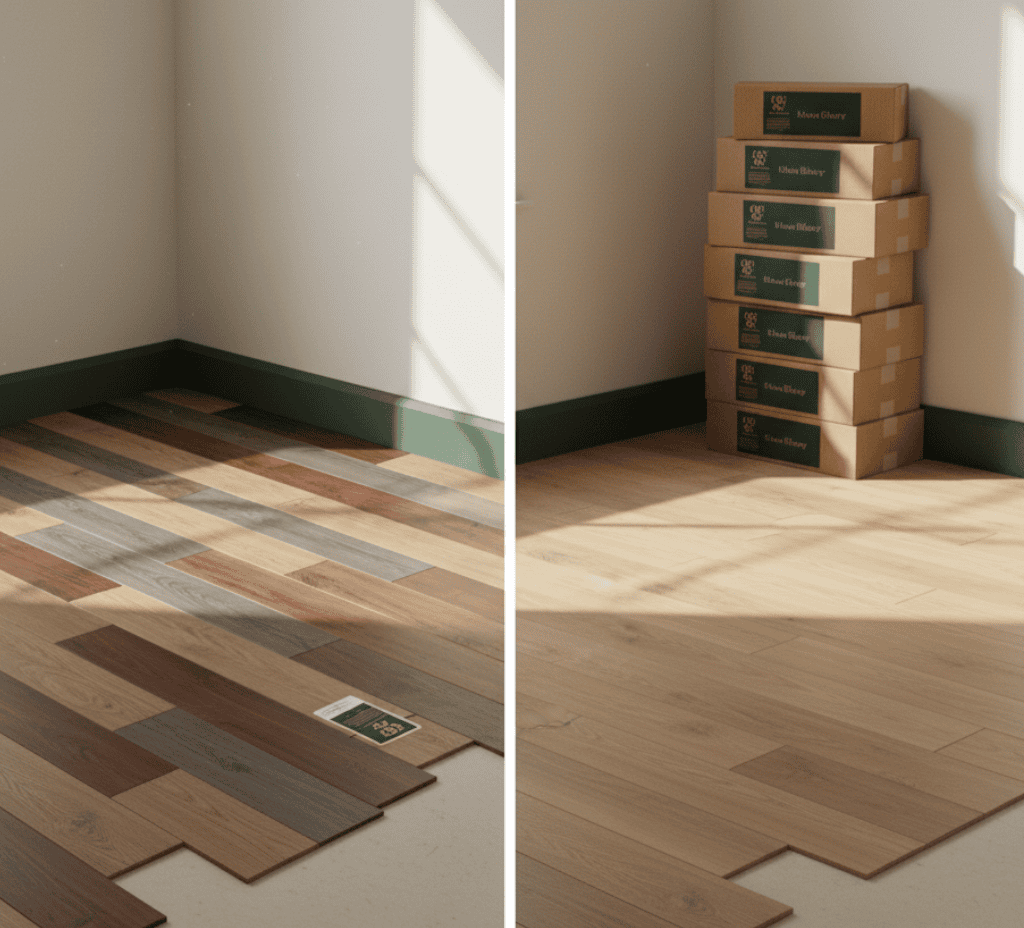

Not Acclimating the Planks

Before laying vinyl planks, it’s important to let them adjust to the temperature and humidity of

the room. Skipping this step can lead to planks expanding or shrinking after installation,

causing gaps, buckling, or uneven surfaces.

Pro Tip

Keep the boxes of flooring in the room for 48–72 hours before starting the installation. In Richmond, VA, seasonal humidity changes make this step even more important.

Skipping Subfloor Preparation

A clean, level, and dry subfloor is critical for a smooth vinyl floor. Dust, dirt, or uneven spots

can prevent planks from sitting flat, leading to creaks, bumps, or adhesion problems.

How to Prepare the Subfloor

● Sweep and mop thoroughly.

● Fill low spots with leveling compound.

● Ensure the floor is completely dry before installation.

Installing Over Old Flooring Without Proper Prep

Do:

● Remove or repair old flooring.

● Check for moisture or damage.

Don’t:

● Lay vinyl directly over loose or damaged surfaces.

● Skip cleaning and leveling.

Choosing the Wrong Underlayment (or Skipping It)

Aesthetic Problems

Even a small installation flaw can ruin the entire look of a floor. Watch out for.

● Crooked first row throws the entire layout out of alignment.

● Narrow last rows or repeating patterns create an unnatural, uneven finish.

● Visible gaps or warped planks immediately lower a home’s appeal and resale value.

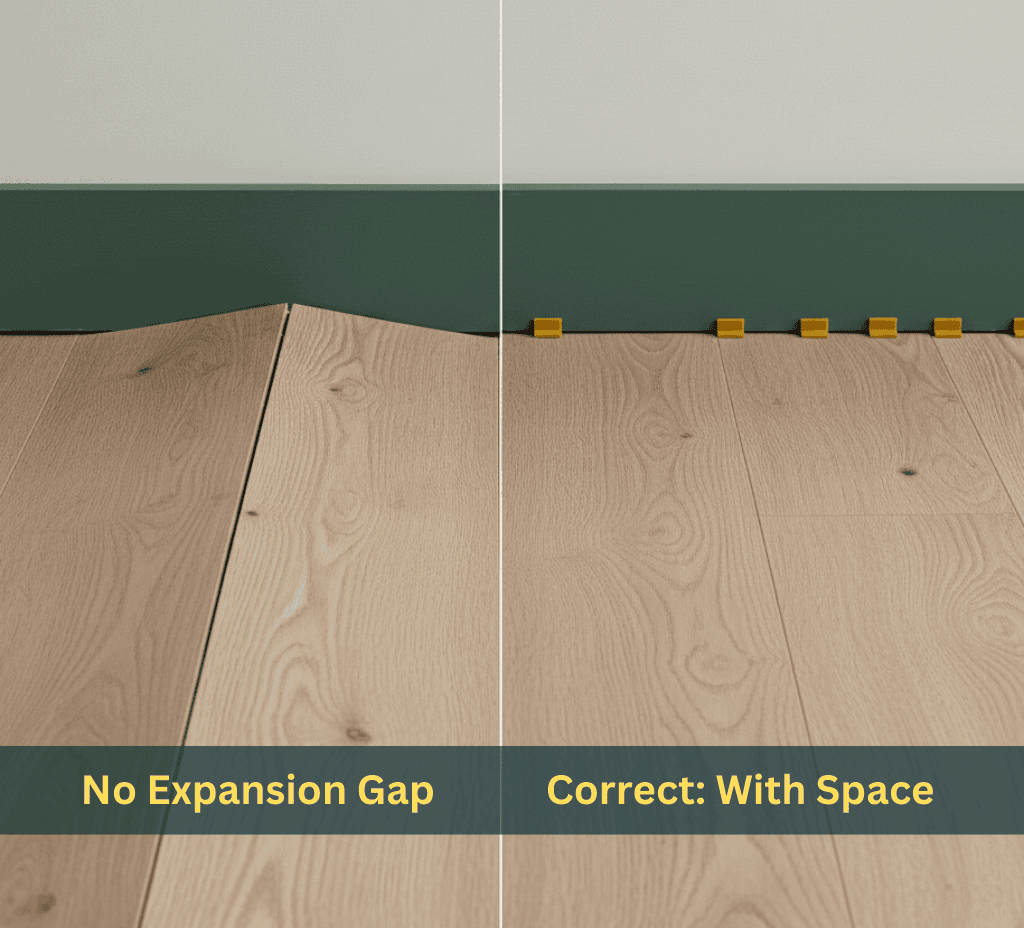

Forgetting Expansion Gaps

Vinyl planks expand and contract with changes in temperature and humidity, so it’s important

to leave a small gap along the walls during installation. Without this space, the floor can

buckle, peak, or push against the baseboards.

Use spacers to maintain about a 1⁄4-inch clearance between the planks and the walls,

allowing the flooring to expand naturally and avoid damage.

Incorrect Layout Planning / First Row Mistakes

The first row sets the foundation for the entire floor. A crooked first row or poor layout can

make the whole floor appear uneven and make finishing the last row difficult. Narrow rows at

the edge can look awkward, and placing similar plank patterns next to each other creates an

unnatural appearance.

Tips & Best Practices:

● Dry-fit the first row before locking or gluing to ensure it’s straight.

● Use a chalk line as a visual guide for alignment.

● Consider the room’s shape, corners, and lighting when planning plank direction.

● Stagger patterns for a natural, visually appealing look.

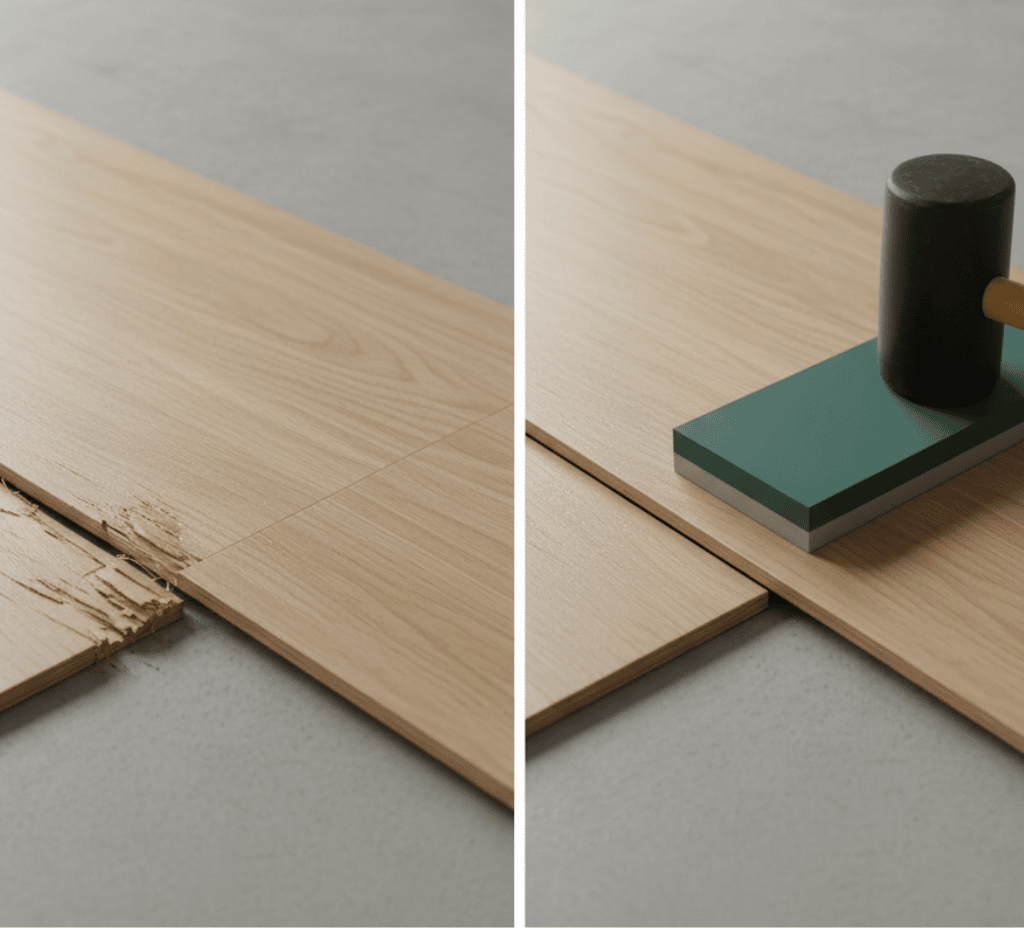

Misaligned or Forced Planks

Forcing planks into place or misaligning them can damage the locking mechanism. This

often leads to gaps forming later or planks popping up over time.

Tips & Best Practices:

● Use a tapping block and soft hammer to gently tap planks into place.

● If a plank doesn’t fit, reset it rather than forcing it.

● Check for uneven subfloor spots that may push planks out of alignment.

VS Table:

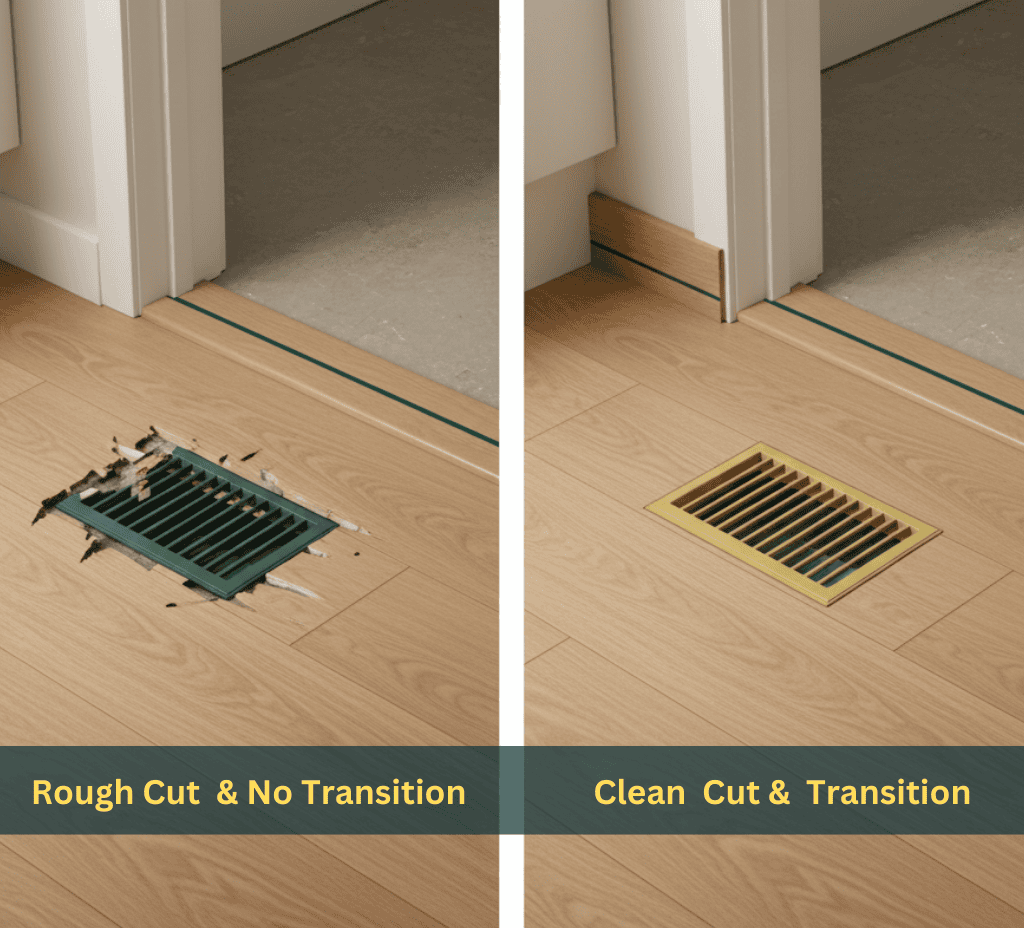

Incorrect Cutting Techniques

Wrong cuts can waste material, create rough edges, or make planks not fit properly. Cutting

near door jambs, vents, or cabinets requires extra care.

Tips & Best Practices:

● Measure twice and cut once.

● Mark cut lines clearly with a pencil or chalk.

● Use a sharp utility knife or saw for precise cuts.

● Account for obstacles like vents, pipes, and door trims.

Not Staggering the Seams

Placing seams in a straight line weakens the floor and makes it look unnatural. Staggered

seams improve stability and visual appeal.

Pro Tip

Offset seams by at least 6 inches between rows. Avoid repeating patterns next to each other.

Leaving Baseboards or Door Trims Untouched

Placing seams in a straight line weakens the floor and makes it look unnatural. Staggered

seams improve stay Not undercutting or removing trims can restrict expansion, leaving visible gaps or requiring

unsightly quarter-round molding. Tips & Best Practices:

● Remove baseboards or undercut door trim to allow planks to slide underneath.

● Check for proper clearance around doors to prevent buckling.

● This ensures a neat, professional-looking finish.

Forgetting Transition Strips, Corners, and Vents

Ignoring transitions can create tripping hazards, gaps, or weak spots. Incorrectly cut or

placed vent cutouts can damage planks.

● Plan all transitions between rooms in advance.

● Measure corners and vents before cutting planks.

● Use proper transition strips for smooth room-to-room flow.

Not Buying Extra Planks

Mistakes, mis-cuts, or damaged planks are common during installation, and running short

can delay the project or create color mismatches. To avoid issues, purchase about 10–15

percent extra material to cover mistakes and future repairs, and store any leftover planks for

later replacements.

Rushing Installation / Ignoring Manufacturer Instructions

Skipping steps or rushing through can void warranties and create long-term issues like

gaps, uneven adhesive, or misaligned planks.

Tips & Best Practices:

● Read and follow the manufacturer’s guidelines carefully.

● Take extra time for tricky areas like corners, doorways, and glue-down planks.

● Avoid rushing, especially in larger rooms where small errors compound.

Post-Installation Mistakes

Even after installation, mistakes can occur: walking on the floor too soon, not cleaning

properly, or skipping furniture pads can cause scratches, dents, or adhesive issues.

Tip:

● Wait for adhesives to cure if using glue-down planks.

● Clean gently and sweep debris to prevent scratches.

● Use furniture pads to protect the surface.

● Double-check final alignment and make any adjustments before finishing.

Consequences of These Mistakes

Installing vinyl plank flooring isn’t just about looks; mistakes during installation can create

serious long-term problems. Here’s what can go wrong if common errors aren’t avoided:

Buckling, Warping, and Gapping

When planks aren’t acclimated, expansion gaps are skipped, or the subfloor is uneven, the

flooring may:

● Buckle up under pressure.

● Warp or curl at the edges.

● Develop gaps between planks, letting in dust and moisture.

Pro Tip

When planks can’t expand or settle properly, they buckle, warp, or separate and these issues only get worse with time. Proper prep now saves you major repair costs later.

Floors Wearing Out Faster

Improper cutting, poor alignment, or skipping underlayment can weaken the floor’s stability.

Over time, this causes:

● More scratches and dents.

● Increased wear in high-traffic areas.

● A noisy, creaking floor that loses its comfort.

Higher Repair and Replacement Costs

A single mistake, like not leaving expansion gaps or forcing planks, can mean ripping up

sections of the floor later. That leads to:

● Paying for extra materials and labor.

● Wasting time re-installing parts of the floor.

● Sometimes replacing the entire floor if problems spread.

Quick Table:

Risk of Voiding Warranty

Most flooring manufacturers include strict installation requirements. Ignoring them can void

the warranty, leaving homeowners unprotected against:

● Plank defects.

● Premature wear.

● Water damage claims.

You know what ?

Even if the flooring itself is high quality, improper installation shifts all

responsibility (and cost) back to you.

Cost Comparison: DIY Mistakes vs Correct Installation

At first glance, skipping steps or rushing installation might seem like a money-saver. But in

reality, these “savings” are short-term. Mistakes often lead to hidden repair costs that far

outweigh the upfront expense of doing it right.

Pro Tip

The numbers make it clear: cutting corners rarely saves money in the long run.

Investing a little more in preparation, the right tools, and careful installation protects both your wallet and your flooring investment.

Tools and Materials You Actually Need (vs. Overkill)

One reason DIY flooring projects go wrong is using the wrong tools or skipping essentials

altogether. Here’s a clear breakdown of what you really need versus what’s just nice-to-have.

Must-Have Tools & Materials

These are non-negotiable for a smooth installation:

Utility knife (with plenty of sharp blades)

Most vinyl planks can be scored and snapped, so a sharp utility knife ensures clean,

precise cuts without splintering. Keep spare blades handy to avoid ragged edges.

Tapping block & soft hammer (rubber mallet)

These help lock planks together without damaging the tongue-and-groove edges. A

regular hammer can crack the plank, so always use soft striking tools.

Spacers

Small but critical; they keep a consistent expansion gap along walls so your floor

doesn’t buckle when it expands. Removing them after installation keeps your layout

stable.

Measuring tape & straight edge

Accuracy is everything. A straight edge ensures straight cuts, while measuring tape

prevents wasted planks and awkward gaps.

Level

A simple 4-foot level helps identify dips or high spots in the subfloor. Installing over

an uneven surface can cause creaks, gaps, or even cracked planks.

Pencil or chalk line

Marking cut lines or reference rows makes it easier to keep the floor layout square to

the walls. A chalk line is especially helpful in large rooms.

Underlayment (if required)

Adds sound absorption, smooths out minor subfloor imperfections, and can act as a

moisture barrier. Some planks have attached underlayment—always check your

product’s requirements.

Nice-to-Have (Makes the Job Easier)

Not essential, but they can save time and improve results:

Pull bar

Especially useful for the last row, where a tapping block won’t fit. It lets you snug

planks tightly against the wall.

Jigsaw or circular saw

While a utility knife works, a saw makes cutting around vents, pipes, and door

frames faster and cleaner.

Floor roller

Required mainly for glue-down vinyl. Rolling the floor ensures even adhesive

contact, reducing bubbles or loose spots.

Knee pads

Vinyl installation is done mostly on your knees; pads prevent discomfort and help

you work longer without strain.

Shop vacuum

A clean subfloor is critical. A vacuum removes dust and debris that could keep

planks from locking together properly.

Pro Tip

Having the right tools ready before starting prevents mistakes like forced planks,

uneven cuts, or missed expansion gaps, all of which are common causes of failed installations.

Mini Case Study: Why Skipping Acclimation is a Big Mistake?

A Richmond, VA homeowner bought luxury vinyl planks in the middle of a humid summer

weekend. Excited to start, they skipped the step of leaving the planks in the room to acclimate.

At first, the floor looked perfect. But within just a few weeks, gaps started to appear along the

seams, and some planks even buckled upward in high-traffic areas.

Maintenance Mistakes After Installation

Even after your vinyl plank floor is installed perfectly, poor maintenance can undo all your

hard work. Avoid these common pitfalls to keep your floor looking new for years:

Using Harsh Cleaners

● Strong chemicals, bleach, or ammonia-based cleaners can damage the protective

wear layer on vinyl planks.

● Stick to pH-neutral floor cleaners or a mild soap-and-water solution.

● Avoid soaking the floor too much water can seep into seams and edges, causing

swelling or warping.

Not Using Felt Pads Under Furniture

● Sliding furniture without protection can scratch or dent your floor.

● Apply felt pads under chairs, tables, and heavy objects.

● Check pads periodically, they wear down over time and need replacement.

Letting Water Sit on the Floor

● Vinyl is water-resistant but not waterproof. Pooled water can penetrate seams or the

subfloor if left too long.

● Immediately wipe up spills, leaks, or water from pets or windows.

● In bathrooms and kitchens, consider mats or rugs in high-risk areas to protect the

floor.

Skipping Regular Cleaning

● Dust, dirt, and grit can scratch the floor surface over time.

● Sweep or vacuum regularly using a soft-brush attachment.

● Avoid vacuums with beater bars, which can damage vinyl.

Ignoring Manufacturer’s Maintenance Guidelines

● Each brand may have specific cleaning and care instructions.

● Following these ensures your warranty remains valid.

A quick “Do / Don’t” maintenance chart for vinyl plank flooring:

Proper maintenance is just as important as correct installation. Even a perfectly installed

vinyl plank floor can lose its durability and aesthetic appeal if neglected.

By following simple steps using gentle cleaners, protecting furniture, promptly wiping spills,

and following manufacturer instructions you can extend the life of your floor, prevent costly

repairs, and keep it looking beautiful for years.

Room-Specific Challenges

Vinyl plank flooring is versatile and durable, but every room has its own unique conditions

that can affect installation and long-term performance. Ignoring these room-specific factors

can lead to buckling, gaps, uneven seams, or even premature wear.

Understanding the challenges each space presents, whether it’s high moisture, uneven

concrete, or large open areas helps you plan your installation carefully. By addressing these

issues in advance, you can ensure your floor remains beautiful, functional, and long-lasting,

while avoiding costly repairs or replacements.

Bathrooms and Kitchens

Bathrooms and kitchens are high-moisture areas. Even water-resistant vinyl can be

damaged if water pools along seams or edges. Installing a vapor barrier or

moisture-resistant underlayment helps protect the floor and maintain its durability.

Basements and Concrete Floors

Basements and concrete floors often present uneven surfaces or hidden moisture issues.

Testing the concrete for moisture and leveling any dips ensures the planks lay flat and prevents buckling or warping over time. Using a moisture-resistant underlayment adds an

extra layer of protection.

Open-Concept Living Rooms

Open-concept living rooms require careful planning of plank layout and seam placement.

Proper staggering of planks and accounting for expansion along long walls prevents gaps or

uneven edges. Planning transitions between rooms in advance ensures a seamless and

professional look.

Pro Tip

Every room presents its own installation challenges. Addressing moisture, subfloor level, and layout from the start ensures your vinyl plank flooring remains durable, functional, and visually appealing for years.

Don’t Start Without a Room Check

A quick review of your room’s shape and conditions can prevent gaps, lifting, and costly mistakes. Set yourself up for a smooth installation.

DIY vs Hiring a Pro: When to Consider Each

Vinyl plank flooring is marketed as DIY-friendly, but not every project is suitable for a

beginner. Understanding your skills, the room conditions, and potential risks can help you

decide whether to tackle the installation yourself or hire a professional. Making the wrong

choice can lead to mistakes that are costly to fix and may even void the manufacturer’s

warranty.

When DIY Works Best

DIY is ideal for:

● Small rooms with simple layouts.

● Level subfloors with minimal preparation.

● Click-lock planks that don’t require adhesive.

● Homeowners with basic tools and patience for measuring, cutting, and laying planks

carefully.

DIY lets you save money and gives a sense of accomplishment, but it requires attention to

detail and time.

When Hiring a Pro Makes Sense

Hiring a professional is recommended if:

● The room is large or irregularly shaped.

● The subfloor needs leveling or moisture testing.

● You are installing glue-down planks or working in moisture-prone areas.

● You want to protect your warranty or ensure a flawless finish quickly.

Pros include expert layout, precision cutting, and peace of mind, though it comes with a

higher upfront cost.

Pros & Cons Table

You know what ?

Deciding between DIY and a professional installer depends on your

comfort level, room complexity, and tolerance for risk. Smaller, simple rooms with level subfloors are perfect for DIY. For larger, moisture-prone, or tricky layouts, a professional ensures a smooth, worry-free installation and protects your investment.

FAQs About Common Mistakes

Many beginners make similar errors. Common mistakes include skipping subfloor

preparation, not acclimating planks, failing to leave expansion gaps, misaligning or forcing

planks, and improper cutting. Other issues include not staggering seams properly, leaving

baseboards in place, and rushing the installation. These mistakes can lead to buckling,

gaps, noise, and even voided warranties, so careful planning is essential.

Uneven subfloors cause gaps, bumps, and creaking, preventing proper locking.

Quick checklist:

● Check the floor level with a level

● Fill low spots with leveling compound

● Sand high spots

● Clean and dry the surface before installing

An uneven subfloor can cause gaps, bumps, or creaking. It can also prevent planks from

locking properly. To prepare:

● Use a level to check the floor.

● Fill dips with leveling compound or sand down high spots.

● Ensure the surface is clean and dry before installation.

Removing baseboards is recommended because it allows planks to slide neatly under

door trims and maintain proper expansion gaps. Leaving baseboards in place can create

uneven edges and restrict plank movement, leading to buckling or gaps.

Expansion gaps prevent buckling and warping as planks expand and contract.

Example spacing:

● 1/4 inch gap around walls and obstacles

● Use spacers to maintain consistency

● Check gaps during installation to avoid future problems

Planks are usually installed parallel to the longest wall or the main source of light. This

enhances visual appeal and makes the room appear larger. For open-concept spaces,

consider sightlines and transitions between rooms.

Proper staggering strengthens the floor and looks natural.

Tips:

● Maintain at least a 6-inch seam offset between rows

● Avoid repeating patterns side by side

● Random stagger patterns create a natural look

Yes, but concrete must be tested for moisture. Moisture barriers or underlayment may be

required. The surface should be level, clean, and dry to prevent buckling or mold issues.

The essential tools include a utility knife, tapping block with soft hammer, spacers,

measuring tape, straight edge, level, and pencil or chalk line. Optional tools such as pull

bars, jigsaws, and floor rollers can make installation easier but are not strictly necessary.

Proper subfloor preparation and correct plank locking are key. Use spacers for expansion

gaps and tapping blocks for snug seams. Avoid forcing planks, as this can damage the

locking mechanism.

Yes, with moisture precautions:

● Use a vapor barrier if recommended

● Seal edges and seams

● Wipe up water promptly

● Consider rugs or mats in high-risk areas

A: Avoid:

● Rushing the installation

● Forcing planks

● Skipping acclimation

● Ignoring expansion gaps

● Misaligning seams

Yes, purchase 10–15 percent more than the room’s calculated area. Extra planks cover

mistakes, breakage, and future repairs, ensuring continuity in pattern and color.

Installation difficulty depends on the room size, subfloor condition, and plank type.

Click-lock planks in small, simple rooms are beginner-friendly. Large areas, glue-down

planks, or uneven subfloors require more skill and may benefit from professional installation.

Conclusion

Installing vinyl plank flooring can be a rewarding DIY project, but even small mistakes can

lead to gaps, buckling, or premature wear. From proper subfloor preparation and acclimation

to leaving expansion gaps, staggering seams, and using the right tools, attention to detail is

essential.

Room-specific challenges, such as moisture in bathrooms, uneven concrete in basements,

or large open-concept areas, require extra planning to ensure a flawless finish. Maintenance

after installation is equally important to protect the floor from scratches, water damage, and

long-term wear.

Deciding between DIY and hiring a professional depends on your experience, room

complexity, and risk tolerance. Small, simple rooms may be perfect for beginners, while

larger or moisture-prone areas often benefit from professional expertise.

By following these guidelines, avoiding common mistakes, and properly caring for your floor,

you can enjoy a durable, beautiful vinyl plank installation that lasts for years. Planning,

patience, and attention to detail are the keys to success.

Plan your installation carefully and gather the right tools before starting. If you’re unsure

about moisture, leveling, or complex layouts, consider consulting a flooring professional to

avoid costly mistakes.